Racemax ITALIA

ITALIAN MADE FASTEST GRAVEL JUST GOT FASTER

Our dream to bring carbon production back to Italy has become a reality at our Italian Factory near Bergamo.

Using our proprietary filament winding and RTM (resin transfer molding) technology, we hand built the fastest gravel frame in the world right here with on our 3T designed machines. This allows us to customize your frame for 1x, 2x, mechanical or electronic shifting upon request.

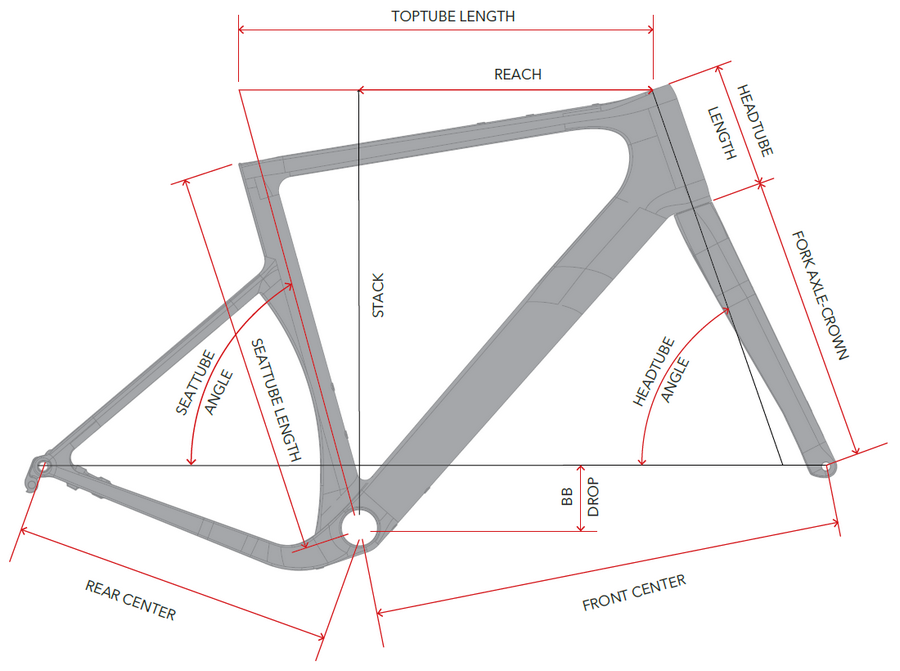

| Size | 51 | 54 | 56 | 58 |

|---|---|---|---|---|

| Rider Height (cm) | 157-171 | 168-180 | 176-186 | 183-195 |

| Rider Height* (inches) | 5'2"-5'7" | 5'6"-5'11" | 5'9"-6'1" | 6'0" 6'5" |

| Stack | 544 | 566 | 586 | 606 |

| Reach | 364 | 374 | 382 | 390 |

| "Road" Headtube | 147 | 161 | 180 | 201 |

| Headtube angle | 69.2 | 70.7 | 71.7 | 72.2 |

| Fork axle-crown | 375 | 375 | 375 | 375 |

| Front center | 612 | 607 | 612 | 622 |

| Rear center | 418 | 418 | 418 | 418 |

| BB drop | 77 | 77 | 75 | 73 |

| Wheelbase | 1018 | 1013 | 1019 | 1028 |

| Toptube length | 518 | 536 | 549 | 563 |

| Seattube length | 463 | 490 | 518 | 545 |

| Seattube angle | 74 | 74 | 74 | 74 |

*Rider heights are approximations. For more accuracy, compare stack/reach with your current bike or visit your 3T retailer.

** RaceMax FORK length is equal to a standard road bike, so this HEADTUBE length can be compared to road bikes. To compare to gravel bikes with standard gravel forks, deduct 25mm from these “road" headtube lengths for a proper comparison.

Close-fitting cutout to shield the rear wheel and achieve the most speed.

No oversized gaps between front tire & downtube for better airflow transition and less turbulence.

The original Exploro set today’s standard for up to 54mm tire clearance. The RaceMax has up to 61mm with 650b"!

Lower downtube aero profile is 75mm wide to fully shield water bottle.

Upper downtube necks down to 50mm to pick up the airflow coming off the front tire.

Reduced depth on smaller sizes to keep frame compliant and keep space for bottles.

Headtube is sizes like a road bike for a narrow 1 1/8”- 1 ¼”steerer for optimal aerodynamics.

Inside that narrow headtube is a big 1 1/2” steerer for best strength and stiffness.

To fit this big steerer inside the narrow headtube, we use the custom MinMax headset.

Fork crown shapes haven’t changed much since brakes were attached there. Now that we have disc brakes, we don’t need that bulk of material and can reshape the crown for better strength, stiffness and weight. Plus better aerodynamics.

With the shorter crown, we can make our forks 25mm (1 inch) shorter than other gravel bikes. Exactly the same as a road fork. This offers better stiffness, lower weight, an easier steering geometry and better aerodynamics.

Dropping the drive-side chainstay improves tire & crank clearance. Dropping the other side as well creates a much more efficient structure behind the BB for higher stiffness & strength as well as lower weight.

Most of our complete bikes come with threaded BBs for the best alignment and to avoid any issues. Yet we avoid gluing threaded alloy rings into the carbon (added weight, complexity and debonding risk). Read more here.

Standard frames require an adaptor to use a 160mm brake rotor. We have integrated that into the frame, meaning you don’t need any extra pieces to attach the brake.

Standard forks require a flip-flop adaptor to set the correct brake rotor size. Our direct-mount pre-sets the caliper for 160mm rotors without any extra pieces.

Self-adjusting bolt angle for higher clamping forces with lower torque.

The new standard for gravel bikes, available for round and oval rails.

Designed specifically for the 3T MORE INTEGRALE.

More information